System Maintenance 101: Ultimate 7-Step Guide for Peak Performance

Welcome to the ultimate guide on system maintenance! Whether you’re managing a computer, server, or industrial machinery, keeping systems in top shape is non-negotiable for efficiency, safety, and longevity. Let’s dive into the essentials.

What Is System Maintenance and Why It Matters

System maintenance refers to the regular activities performed to keep a system—be it software, hardware, or mechanical—running efficiently and reliably. It’s not just about fixing problems; it’s about preventing them before they occur.

Defining System Maintenance

At its core, system maintenance encompasses all actions taken to ensure that a system continues to operate as intended. This includes routine inspections, updates, repairs, and optimizations. The goal is to minimize downtime, reduce costs, and extend the lifespan of the system.

- Applies to IT systems, industrial equipment, vehicles, and more

- Involves both preventive and corrective actions

- Can be manual or automated depending on the system

Types of Systems Requiring Maintenance

Different systems demand different maintenance strategies. For example, an enterprise IT network requires software patching and security updates, while a manufacturing plant needs lubrication, calibration, and part replacements.

- IT Systems: Servers, databases, operating systems, cloud platforms

- Mechanical Systems: HVAC units, conveyor belts, engines

- Electrical Systems: Power grids, circuit breakers, transformers

“Preventive maintenance can reduce breakdowns by up to 50% and extend equipment life by 20–40%.” — International Society of Automation (ISA)

The 7 Core Types of System Maintenance

Understanding the different types of system maintenance is crucial for implementing the right strategy. Each type serves a unique purpose and is suited to specific scenarios.

1. Preventive Maintenance

Preventive maintenance involves scheduled tasks designed to prevent failures before they happen. This is one of the most effective forms of system maintenance, especially in high-availability environments.

- Examples: Replacing filters, updating software, cleaning components

- Benefits: Reduces unexpected downtime, lowers repair costs

- Tools: Maintenance management software like UpKeep or Maintenance Connection

2. Corrective Maintenance

Also known as reactive maintenance, this type is performed after a failure has occurred. While it’s often unavoidable, relying solely on corrective maintenance can be costly and inefficient.

- Best used for non-critical systems with low failure impact

- Drawbacks: High downtime, potential safety risks

- Example: Rebooting a crashed server or replacing a blown fuse

3. Predictive Maintenance

Predictive maintenance uses data and analytics to predict when a system is likely to fail. Sensors and monitoring tools collect real-time performance data to trigger maintenance only when needed.

- Common in industries like aviation, energy, and manufacturing

- Technologies used: Vibration analysis, thermal imaging, AI-driven diagnostics

- Resource: Learn more at ASME’s guide on predictive maintenance

Benefits of Effective System Maintenance

Proper system maintenance isn’t just a technical necessity—it’s a strategic advantage. Organizations that prioritize maintenance see measurable improvements across multiple areas.

Increased System Reliability

Regular maintenance ensures that systems operate consistently without unexpected failures. This is especially critical in sectors like healthcare, finance, and transportation.

- Fewer outages mean higher user satisfaction

- Reliable systems support business continuity

- Example: Hospitals rely on uninterrupted power and medical device functionality

Cost Savings Over Time

While maintenance requires upfront investment, it saves money in the long run by avoiding expensive emergency repairs and replacements.

- A study by the U.S. Department of Energy found that every $1 spent on preventive maintenance saves $4–$7 in corrective costs

- Extends asset lifecycle, delaying capital expenditures

- Reduces waste from inefficient operations

Improved Safety and Compliance

Well-maintained systems are safer systems. Regular checks help identify hazards before they lead to accidents.

- Compliance with OSHA, ISO, and other regulatory standards

- Reduces risk of fire, electrical shock, or mechanical failure

- Documentation of maintenance activities supports audits

“Organizations with structured maintenance programs report 30% fewer workplace incidents.” — Occupational Safety and Health Administration (OSHA)

Essential Tools and Technologies for System Maintenance

Modern system maintenance relies heavily on specialized tools and software to streamline processes and improve accuracy.

Maintenance Management Software (CMMS)

Computerized Maintenance Management Systems (CMMS) are platforms that help schedule, track, and analyze maintenance tasks.

- Features: Work order management, inventory tracking, reporting dashboards

- Popular options: IBM Maximo, Fiix, Hippo CMMS

- Enables teams to automate reminders and prioritize tasks

Monitoring and Diagnostic Tools

These tools provide real-time insights into system health, allowing for proactive interventions.

- Network monitoring: Tools like Nagios or SolarWinds for IT infrastructure

- Industrial sensors: Measure temperature, pressure, vibration, etc.

- AI-powered analytics: Detect anomalies before they escalate

Automation and AI in Maintenance

Artificial intelligence is revolutionizing system maintenance by enabling smarter decision-making.

- Predictive algorithms forecast equipment failure with high accuracy

- Chatbots assist technicians with troubleshooting guides

- Machine learning models optimize maintenance schedules based on usage patterns

Best Practices for Implementing System Maintenance Programs

Creating a successful maintenance program requires planning, discipline, and continuous improvement.

Develop a Comprehensive Maintenance Plan

A well-documented plan outlines what needs to be maintained, how often, and by whom.

- Inventory all critical assets

- Define maintenance intervals based on manufacturer guidelines or historical data

- Assign responsibilities to team members

Train and Empower Your Team

Skilled personnel are the backbone of any maintenance strategy.

- Provide regular training on new tools and procedures

- Encourage certification programs (e.g., CompTIA, CMRP)

- Foster a culture of accountability and safety

Track Performance with KPIs

Key Performance Indicators (KPIs) help measure the effectiveness of your maintenance efforts.

- Mean Time Between Failures (MTBF)

- Mean Time to Repair (MTTR)

- Overall Equipment Effectiveness (OEE)

- Planned Maintenance Percentage (PMP)

“Companies that track maintenance KPIs improve operational efficiency by up to 25%.” — Aberdeen Group

Common Challenges in System Maintenance and How to Overcome Them

Even the best-laid plans can face obstacles. Recognizing these challenges early allows organizations to adapt and succeed.

Lack of Resources or Budget

Many organizations delay maintenance due to budget constraints, but this often leads to higher costs later.

- Solution: Present ROI analysis to stakeholders showing long-term savings

- Prioritize critical systems first

- Explore phased implementation or cloud-based CMMS to reduce upfront costs

Poor Data Collection and Analysis

Without accurate data, maintenance decisions are guesswork.

- Solution: Invest in IoT sensors and centralized data platforms

- Standardize data entry across teams

- Use dashboards to visualize trends and anomalies

Resistance to Change

Employees may resist new tools or processes, especially if they’re used to reactive maintenance.

- Solution: Involve staff in planning and training

- Showcase quick wins from early implementations

- Highlight personal safety and job security benefits

Future Trends in System Maintenance

The field of system maintenance is evolving rapidly, driven by technological advancements and changing business needs.

Rise of Industry 4.0 and Smart Maintenance

Industry 4.0 integrates cyber-physical systems, the Internet of Things (IoT), and cloud computing to create intelligent maintenance ecosystems.

- Machines communicate their status and request service autonomously

- Digital twins simulate real-world systems for testing maintenance scenarios

- Real-time data enables dynamic scheduling and resource allocation

Green and Sustainable Maintenance

As sustainability becomes a global priority, maintenance practices are adapting to reduce environmental impact.

- Using eco-friendly lubricants and cleaning agents

- Recycling worn parts and reducing waste

- Optimizing energy consumption through efficient system tuning

Remote and Autonomous Maintenance

With remote work and automation on the rise, maintenance is becoming less dependent on physical presence.

- Drones inspect hard-to-reach infrastructure like wind turbines

- Robots perform repetitive tasks like lubrication or welding

- Remote experts guide on-site technicians via AR/VR headsets

“By 2025, 60% of industrial maintenance will involve some form of remote support or automation.” — Gartner Research

System Maintenance in Different Industries

The principles of system maintenance apply universally, but implementation varies by industry.

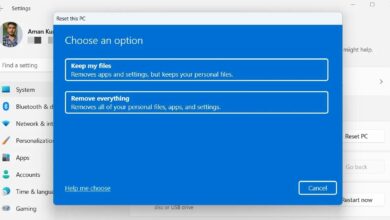

Information Technology (IT)

In IT, system maintenance ensures servers, networks, and applications remain secure and functional.

- Tasks: Patch management, database optimization, firewall updates

- Tools: Ansible, Puppet, Microsoft SCCM

- Best practice: Schedule maintenance during off-peak hours to minimize disruption

Manufacturing

Manufacturers rely on continuous operation, making preventive and predictive maintenance essential.

- Focus on minimizing unplanned downtime

- Use condition-based monitoring on production lines

- Follow Total Productive Maintenance (TPM) methodology

Healthcare

Hospitals depend on life-saving equipment that must be maintained to the highest standards.

- Regular calibration of imaging machines (MRI, CT scanners)

- Biomedical engineering teams conduct routine checks

- Compliance with FDA and Joint Commission regulations

What is the difference between preventive and predictive maintenance?

Preventive maintenance is scheduled based on time or usage (e.g., “change oil every 3 months”), while predictive maintenance uses real-time data to determine when maintenance is actually needed. Predictive is more efficient because it avoids unnecessary servicing.

How often should system maintenance be performed?

Frequency depends on the system type, usage, and environment. Critical systems may require daily checks, while others might need quarterly or annual maintenance. Always follow manufacturer recommendations and adjust based on performance data.

Can small businesses benefit from system maintenance programs?

Absolutely. Even small businesses can avoid costly breakdowns and extend equipment life with basic preventive maintenance. Cloud-based CMMS tools make it affordable and easy to get started.

Is automation replacing human technicians in system maintenance?

No, automation is augmenting human capabilities, not replacing them. Technicians are still needed for complex diagnostics, decision-making, and oversight. Automation handles repetitive tasks and data processing, freeing up experts for higher-value work.

What are the first steps to start a system maintenance program?

Begin by auditing your current systems, identifying critical assets, and setting maintenance goals. Then choose a CMMS tool, train your team, and start with a pilot program on one piece of equipment before scaling up.

System maintenance is far more than a technical checklist—it’s a strategic imperative for reliability, safety, and efficiency. From preventive routines to AI-driven predictions, the right approach can transform how organizations operate. By investing in tools, training, and data-driven decisions, businesses can reduce costs, extend asset life, and stay ahead in an increasingly competitive landscape. Whether you’re managing a single server or an entire factory, a proactive maintenance mindset is the key to long-term success.

Further Reading: